Datasheet

DownloadPapers

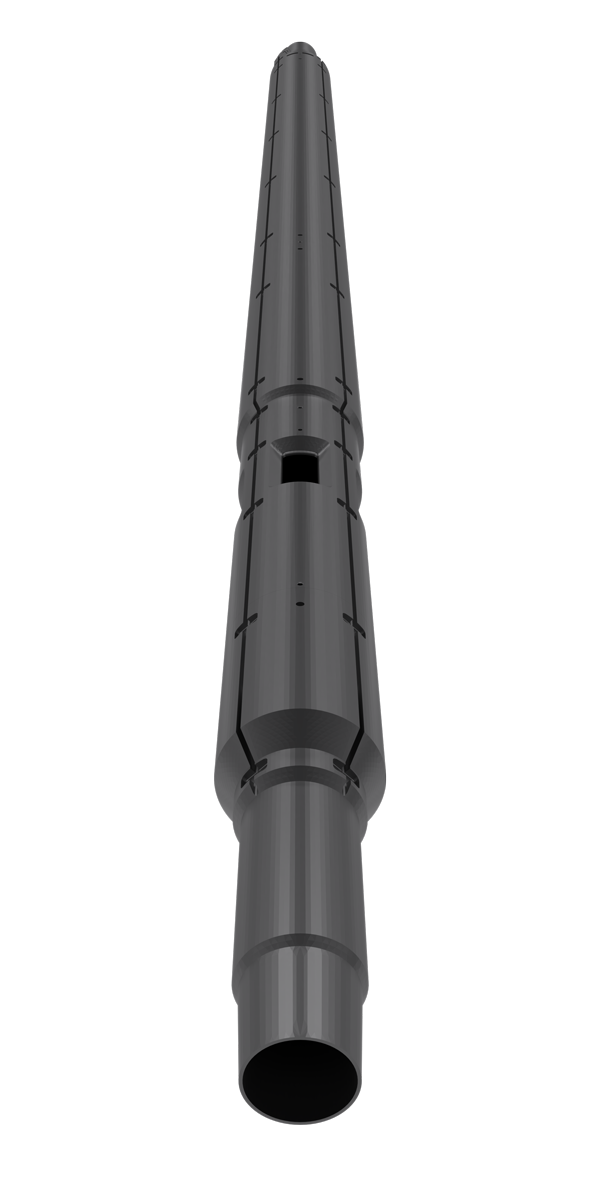

ALL ELECTRIC INTELLIGENT COMPLETION SYSTEM - INTEGRATING THE FUTURE ALL ELECTRIC

Abstract

The continued rising costs involved in oil and gas extraction, particularly in ultradeep waters, requires the optimization and automation of production/injection wells to improve ultimate recovery and to make offshore field exploitation economically viable. In the Brazilian Pre-Salt conventional Direct Hydraulic Intelligent Completion Systems are commonly employed to achieve these objectives. That means the installation of hydraulic controlled downhole flow devices at each potentially active injection/production zone in the well, with. simultaneous real-time monitoring of all devices. Due to Pre-Salt’s critical and harsh scenario, reliability and reduction of costs and operational risks are key requirements for such systems. However, there are major technological challenges in fulfilling these requirements because of the great depths of the reservoirs, ultradeep water sites, high pressures and temperatures and high complexity of the communication between the surface and the well. In order to overcome these challenges, an All Electric Intelligent System can replace those conventional Direct Hydraulic ones, yielding a simpler architecture and higher overall reliability and availability. This paper presents the development of an All Electric Intelligent Completion System (eIC) aimed at Pre-Salt applications, comprising the entire subsea interface and communication system. The technological challenges and rigorous qualification and reliability tests are discussed.

Contact

Get inContact

Fill in your contact information

and we’ll get back to you shortly.