O desafio

A formação de hidratos de gás – sólidos cristalinos consistindo em moléculas de água e uma molécula de gás hospedeira – em condições específicas de temperatura e pressão. Esses compostos se assemelham ao gelo e podem se formar em temperaturas acima da formação de gelo. A formação desses hidratos também pode representar desafios significativos. Eles podem causar danos aos equipamentos submarinos, levando a acidentes ambientais, interrupções na produção e aumento de custos. As soluções atuais no mercado não estão isentas de desafios, que exploraremos mais adiante.

Nossa solução

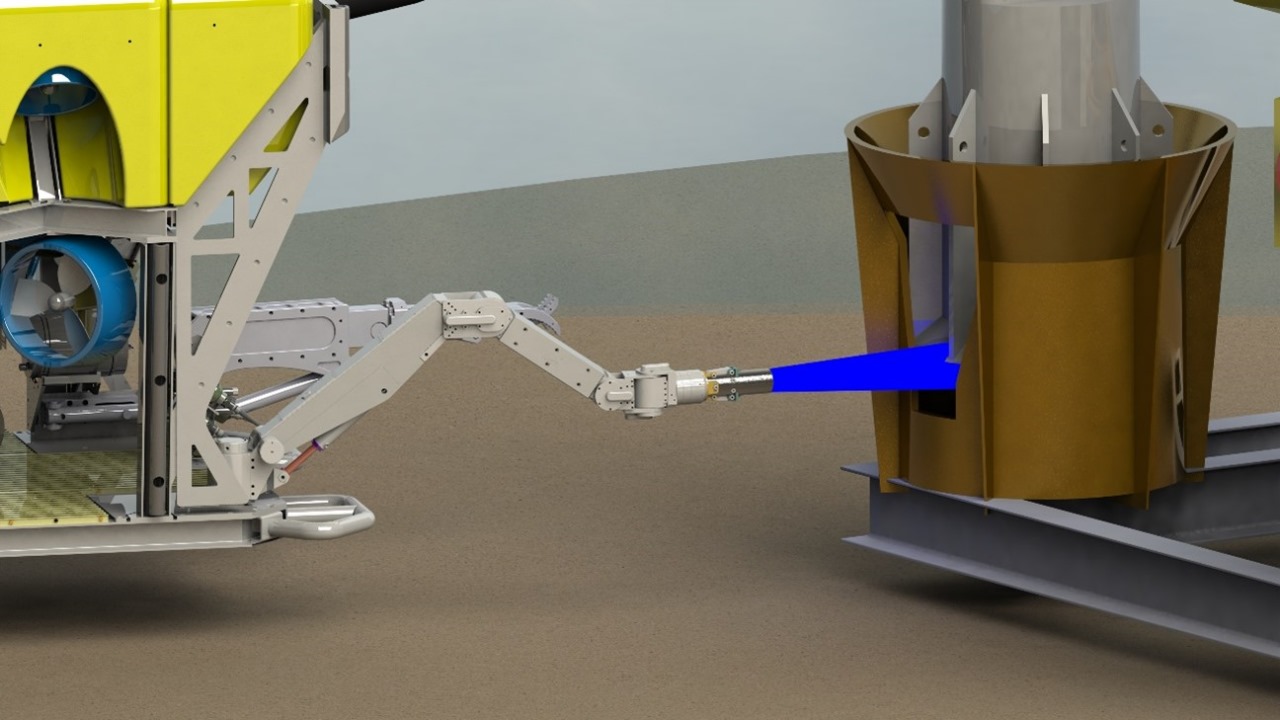

O Laser Cyclops oferece uma solução precisa e eficiente para remover hidratos dos equipamentos de exploração e produção de petróleo e gás submarinos. Operado por ROVs de classe mundial, o sistema utiliza radiação laser de alta potência para direcionar massas de hidratos, garantindo uma dissociação direta rápida e segura. Sua transferência de calor eficiente reduz o tempo de intervenção, enquanto a operação em embarcações menores reduz os custos em até 10 vezes em comparação com os métodos tradicionais. Com mobilidade aprimorada e capacidade de resposta rápida, o Cyclops se destaca como uma solução de alto valor para desafios críticos offshore.

Vantagens

- Alta sensibilidade

- Monitoramento de região espacial (não apenas de ponto específico)

- Diferenciação de algumas classes de materiais

- Baixo consumo de energia

Entre emContato

Preencha suas informações corretamente e entraremos em contato em breve.

Artigos

Abstract

One of the biggest problems in underwater installations for oil and gas production is the hydrate formation in equipments as MCV, valves, tree caps and Wet Christmas Trees. That hydrate needs to be retired because it can restrain the equipment´s operation achieving the production and creating operational and ambient risks. The way to do that is to warm making it pass from the solid state to gaseous state loosen of the structure where it was formed. Nowadays the local warming is done through quimical reagents (Self Generated Nitrogen – SGN) that, by the equipment localization in deep ocean, becoming a complex and big cost operation involving the need of vessels. In this article we propose a tool development using compact high power lasers as energy source directly applied and absorbed in a specific local.

Abstract

The formation of gas hydrates on oil and gas production equipment in deep water can hinder subsea operations, often requiring removal by using expensive and time-consuming methods that can damage the equipment. This paper discusses simulations and experimental tests to evaluate a lower-cost, safer, and more efficient tool under development to remove the hydrates by dissociation through radiation from a high-power laser installed on a Remotely Operated Vehicle (ROV).

The laser source used in the first phase was a blue (445 nm) diode laser of 730 W, while an 1800 W source is currently used for the second phase. Depending on the scenario and material, the laser beam can either irradiate the hydrate formation to heat it and achieve the necessary temperature for dissociation, or it can be aimed at equipment adjacent to the formation, with laser beam spot size and power enough to transmit the necessary heat to the hydrate, without damaging the equipment. Simulations and experimental tests to optimize the parameters were performed to ensure that the required temperatures are reached.

Metal samples and materials similar to hydrates were used in simulations and lab tests in air and in water, and under various laser parameters, demonstrating that heating from deep ocean water temperatures found near subsea equipment (4°C or slightly higher, depending on the depth) up to hydrate dissociation temperatures (17°C–26°C) can be attained with the proposed tool. Additionally, the comparison between the simulations and the experimental results showed good agreement. This paper focuses on the experimental and simulated results obtained with a steel disk and on experimental results for a metal tube, discussing how the ability to reach the temperatures required for dissociation is affected by the water temperature and flow, how far the radiation propagates in water before reaching the target, the temperature distribution on the target, and the irradiation time.

Simulations and experimental results obtained with a high-power-laser tool for deep-water dissociation of hydrates are discussed. The lab tests provided reliability and adjustments for the simulations, in addition to performance estimates for the prototype. The tool is a safer and lower-cost method to dissociate hydrates interfering with the operation of oil and gas production equipment in deep water.

Abstract

This paper discusses experimental tests conducted within a laboratory setting to facilitate the advancement of a proposed hydrate dissociation tool for subsea applications. The tool was designed to be operated and powered employing an underwater Remotely Operated Vehicle (ROV) at depths of 600 m – 3500 m, or even deeper. It is based on a high-power blue diode laser. Hydrate dissociation occurs by transferring heat from the laser radiation to the hydrate either by direct absorption of the laser radiation or by heat conduction from adjacent equipment parts absorbing the radiation. Initially developed for subsea hydrate dissociation, its configuration may be adapted for other applications, such as underwater laser cutting, removal of paraffin, or removal of sun coral from ship hulls by using a different laser source in the tool or by implementing other project changes. The laboratory tests and simulations are being undertaken by using two prototypes (one equipped with a 700 W and the other with an 1800 W laser) to guarantee a compact and efficient design before embarking on field trials. The power density and spatial behavior of the laser beam were investigated. A preliminary hydrate dissociation investigation was performed by observing the light/material interaction with ice and THF hydrate samples.

Finally, the limit for the laser radiation on polymeric insulating materials for pipes and equipment (PU) was evaluated.