O desafio

Sistemas de completação inteligente são a melhor opção para selecionar zonas de produção, garantindo uma gestão eficiente do reservatório e aumentando a recuperação de petróleo e gás. No entanto, a baixa confiabilidade dos sistemas hidráulicos e as limitações de multiplexação ainda dificultam seu uso completo.

Nossa solução

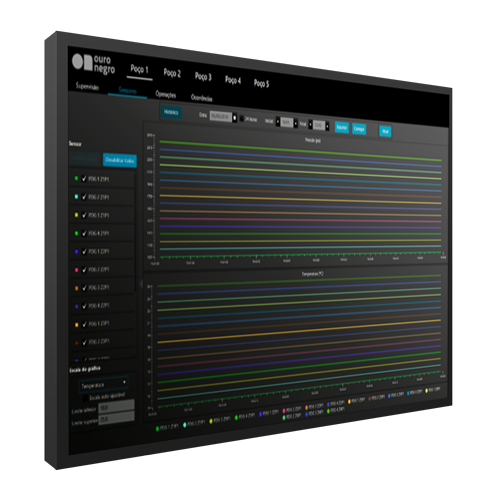

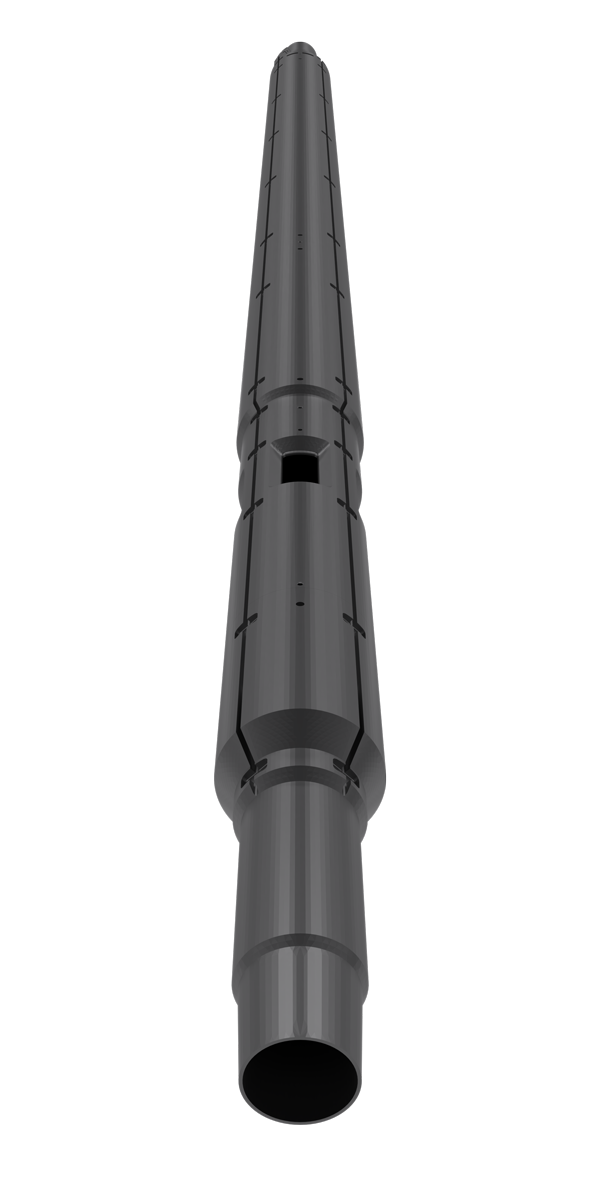

A eICV é uma válvula de controle de entrada altamente confiável, baseada em um sistema de atuação totalmente elétrico integrado a um sistema de monitoramento de poços. Este equipamento inovador permite o controle preciso do fluxo de injeção ou produção em poços de águas profundas, sob temperaturas extremas, altas pressões e taxas de fluxo significativas.

A eICV é uma válvula de controle de entrada altamente confiável, baseada em um sistema de atuação totalmente elétrico integrado a um sistema de monitoramento de poços. O controle infinito da posição de abertura da válvula, e o sofisticado perfil de produção de fluxo permitem o controle ideal de produção e injeção de cada zona do reservatório.

Diversos eICVs podem ser instalados no poço, compartilhando um único cabo de fundo com o sistema de monitoramento de poços totalmente integrado, aumentando assim a recuperação de petróleo e reduzindo os custos operacionais.

O sistema de completação totalmente elétrica é a melhor escolha para a gestão da produção de poços. Ele possui um conceito robusto, design compacto e sistemas avançados de controle e feedback.

Vantagens

- Operação elétrica

- Múltiplas válvulas compartilhando um único cabo elétrico no mesmo poço

- Choke variável

- Mudanças rápidas e bidirecionais na posição do estrangulador

- Sistemas de sensoriamento redundantes para posição do estrangulador, feedback e diagnósticos

- Sensores integrados de pressão e temperatura para monitorar espaços de anel e tubulação

- Revestimento resistente à erosão com insertos de carboneto de tungstênio

- Alta força axial para remover acúmulo de incrustações nos estranguladores

- Sistema de sobreposição mecânica de abertura/fechamento usando métodos padrão de wireline

- Longo ciclo de vida com alta confiabilidade em ambientes adversos

- Projetado para temperaturas extremas, altas pressões e taxas de fluxo significativas

- Muitas válvulas podem ser instaladas no poço, compartilhando um único cabo elétrico

Entre emContato

Preencha suas informações corretamente e entraremos em contato em breve.

Artigos

Abstract

Brazilian Pre-Salt wells located in ultradeep water, capable of producing 70,000 barrels per day, have been, for years, strong candidates for Electric Intelligent Well Completions as means to increase the recovery factor of the fields in Santos Basin. For this purpose, an R&D project for an Electric Inflow Control Valve for 4-1/2 in. tubing string size, following a methodology for Technology Readiness Level progression and reliability adopted by the biggest Brazilian oil company, was carried out from 2014 to 2019.

Environmental conditions, like pressures up to 16,500 psi, temperatures up to 150 °C [302 °F] and differential pressure opening of 1,500 psi, were challenging to the tool design. Additionally, during the electric valve’s development, there was no technical specification for Electric Intelligent Well Completions, so standards like API 17F for the vibration of the embedded electronics boards were also followed.

The tool was divided into physical modules as part of a development strategy. That revealed to be a good approach, as some of those demanding specifications were not yet met in 2019 for testing the fully assembled prototype in any Brazilian laboratory. Test fixtures for selected modules, which would later be integrated into the prototype, were developed so that those parts could be tested individually. The full-scale prototype was then fully assembled and mechanically tested to attend the specified operational static axial loads and cyclic loading and unloading. A second full-scale prototype was built to perform flow characterization and erosion tests. At the end of the development, a System Integration Test, with a spool of tube encapsulated cable simulating their predicted length in a field installation, was performed to prove the actuation and sensing functionalities of the two prototypes with the subsea control boards and human-interface machine.

Results from the testing program and the performance the electromechanical actuation led to a second phase of the Electric Inflow Control Valve development focusing on improving the flow portion to achieve the resistance to 3,000 psi of differential pressure while opening. Moving from a printed-circuit board to a hybrid technology for the valve’s embedded electronics is also a necessary step to increase the reliability of the system and meet the operator’s target. By using the same concept-proven electromechanical actuator, with the addition of a fail-safe device, an Electric Surface-Controlled Subsurface Safety Valve is being developed. Both projects are expected to achieve the TRL 6 by the end of 2024.

Abstract

Although Intelligent Completion is the fastest-growing completion solution worldwide, low reliability, multiplex limitation and data lack of existing solutions still hamper its full use. The inflow control valve is the main component to ensure selectivity between production zones for better reservoir management, contributing to an increase in the oil recovery factor of fields. In the same way, the downhole safety valve (subsurface safety valve) is the component responsible for preventing the uncontrolled flow of hydrocarbons to the external environment, through the production or injection tubing, and to allow safe closure in the event of catastrophic damage to subsea or surface equipment. However, low reliability, when being used in long-term operations, of hydraulic systems became inflow control valves and subsurface safety valves failures the most common cause of well intervention. Therefore, the objective of this paper is to present the R&D background, challenges, and lessons learned in the development of an electrically powered actuator with low power consumption applied to a prototype of an electric inflow control valve and a prototype of subsurface safety valve following technical specifications of ultradeep water Brazilian Pre-Salt wells. The paper also presents the methodology used to design the valves focused on high reliability in long-term operations (27 years of MTTF). In conclusion, the paper presents that this new downhole actuator concept is possible to implement in both valves for ultradeep water wells, being able to actuate with low power consumption.